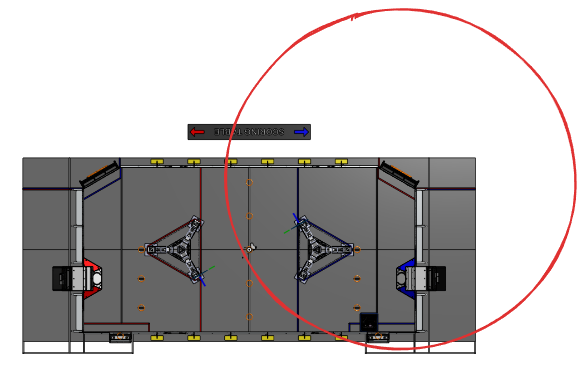

This is a design a process notes document for a launcher made for “notes” as part of the 2024 First Robotics Compeition

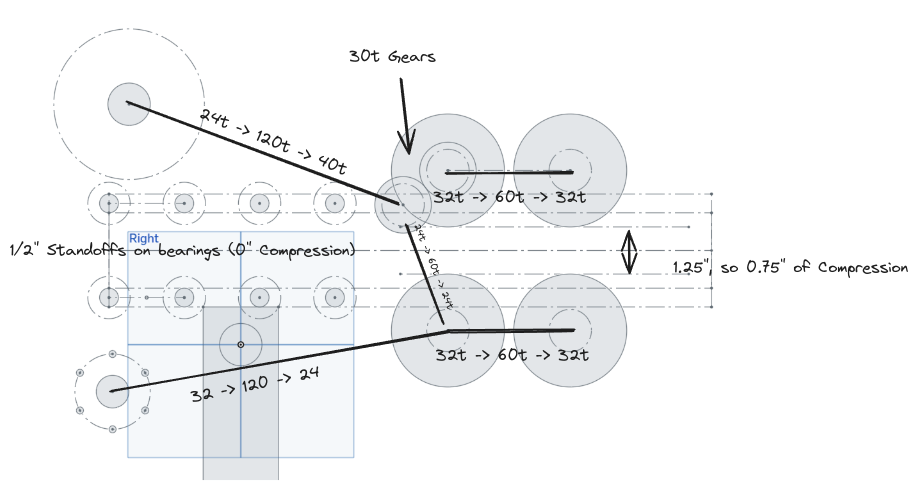

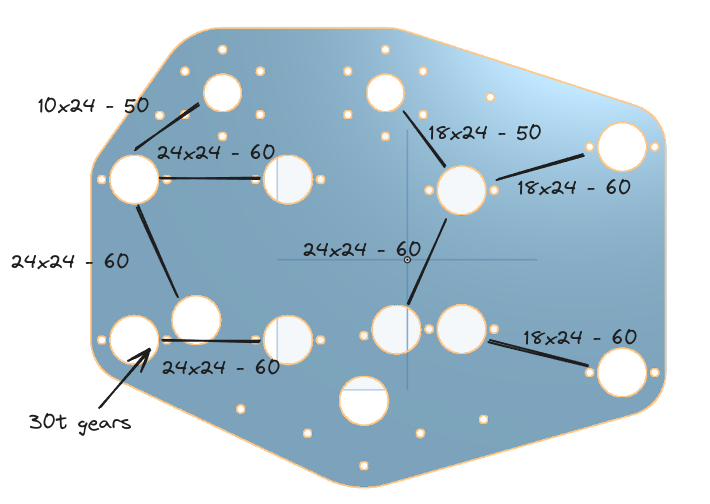

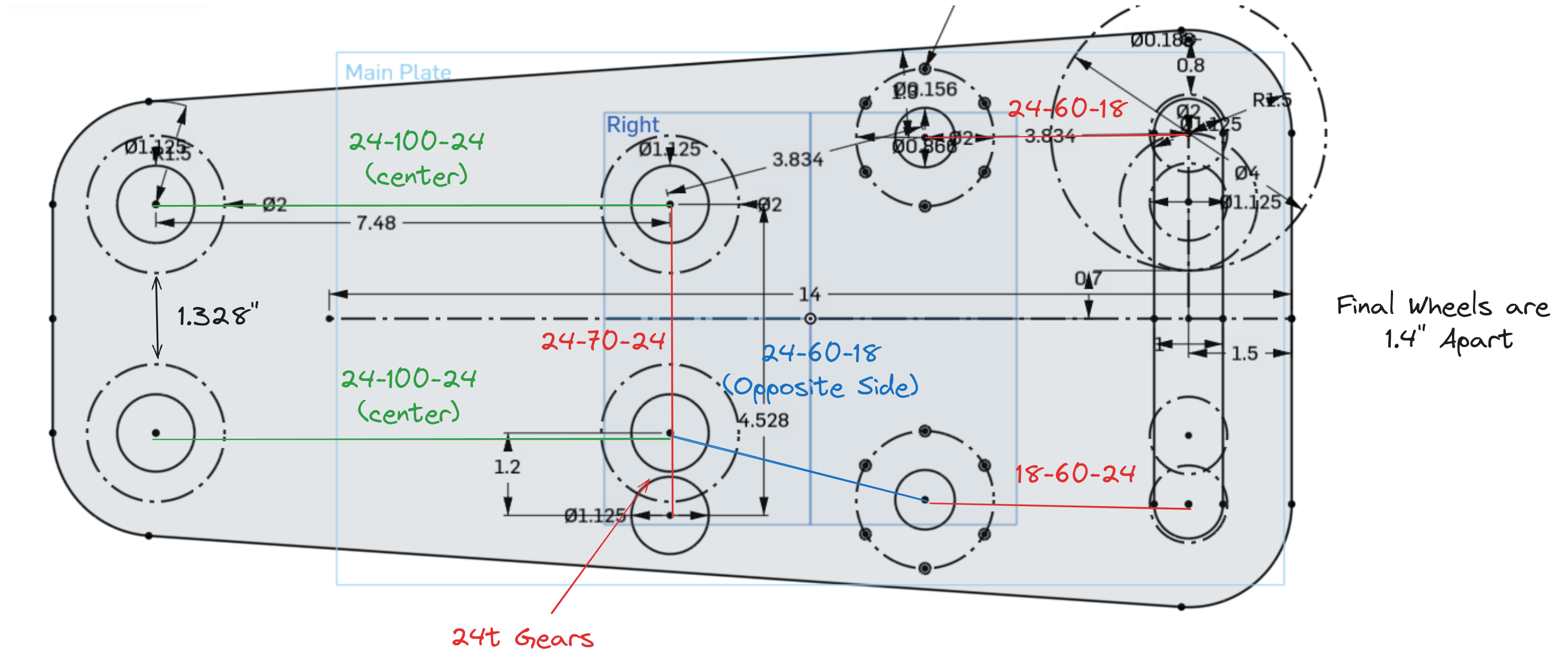

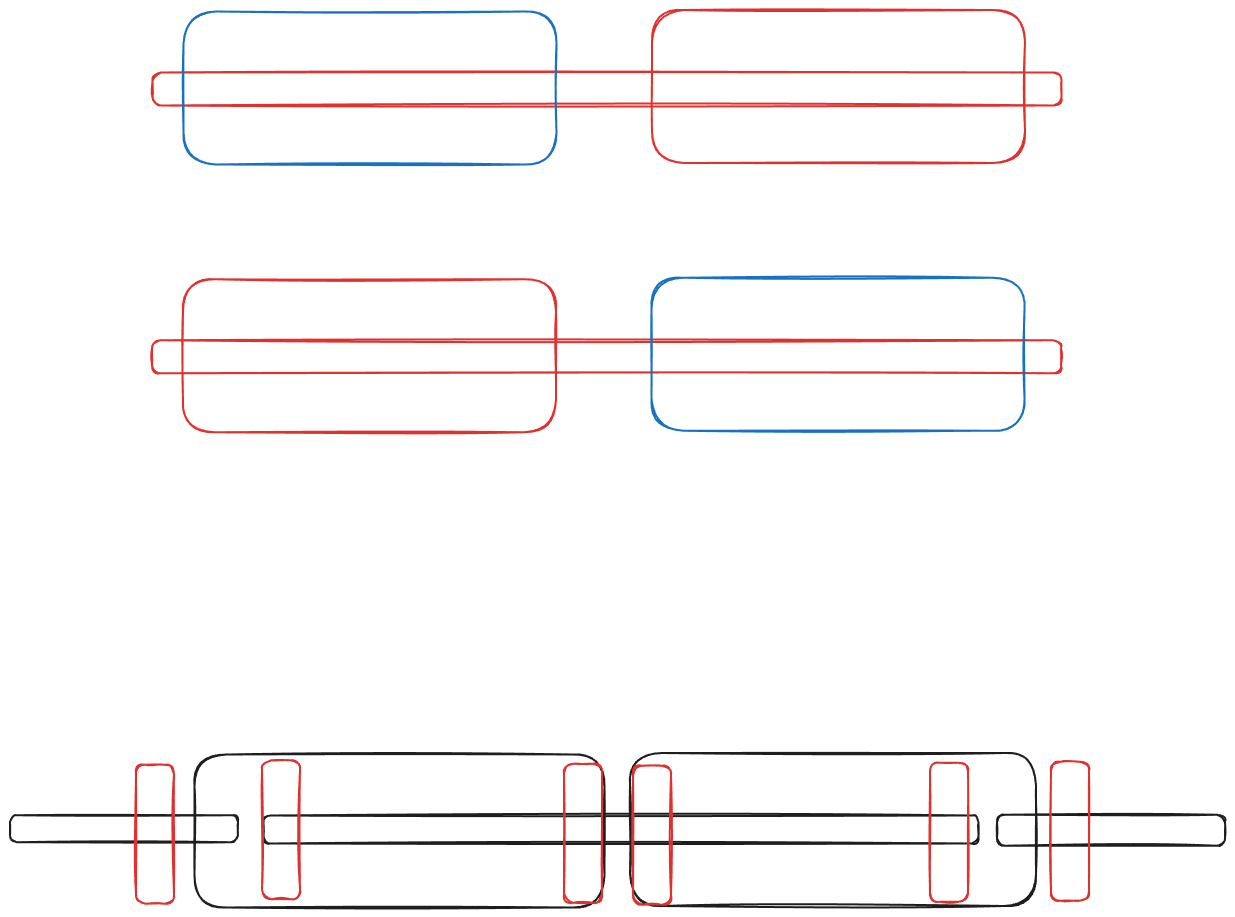

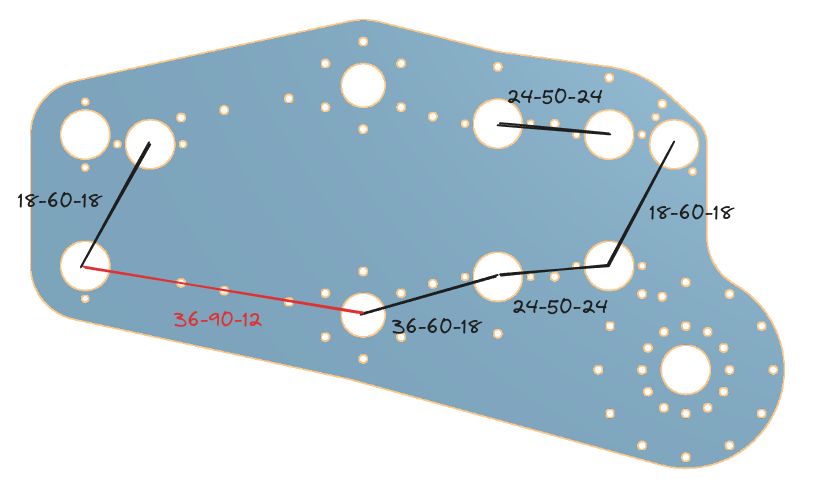

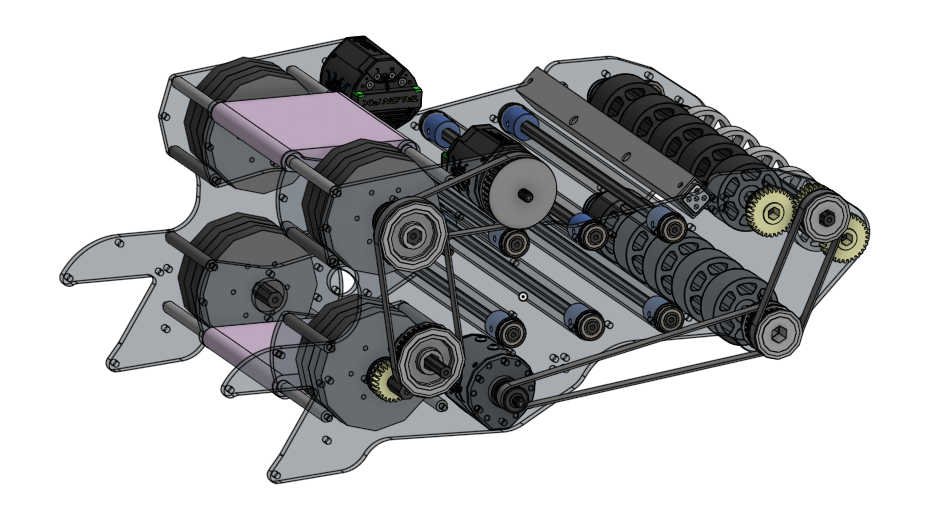

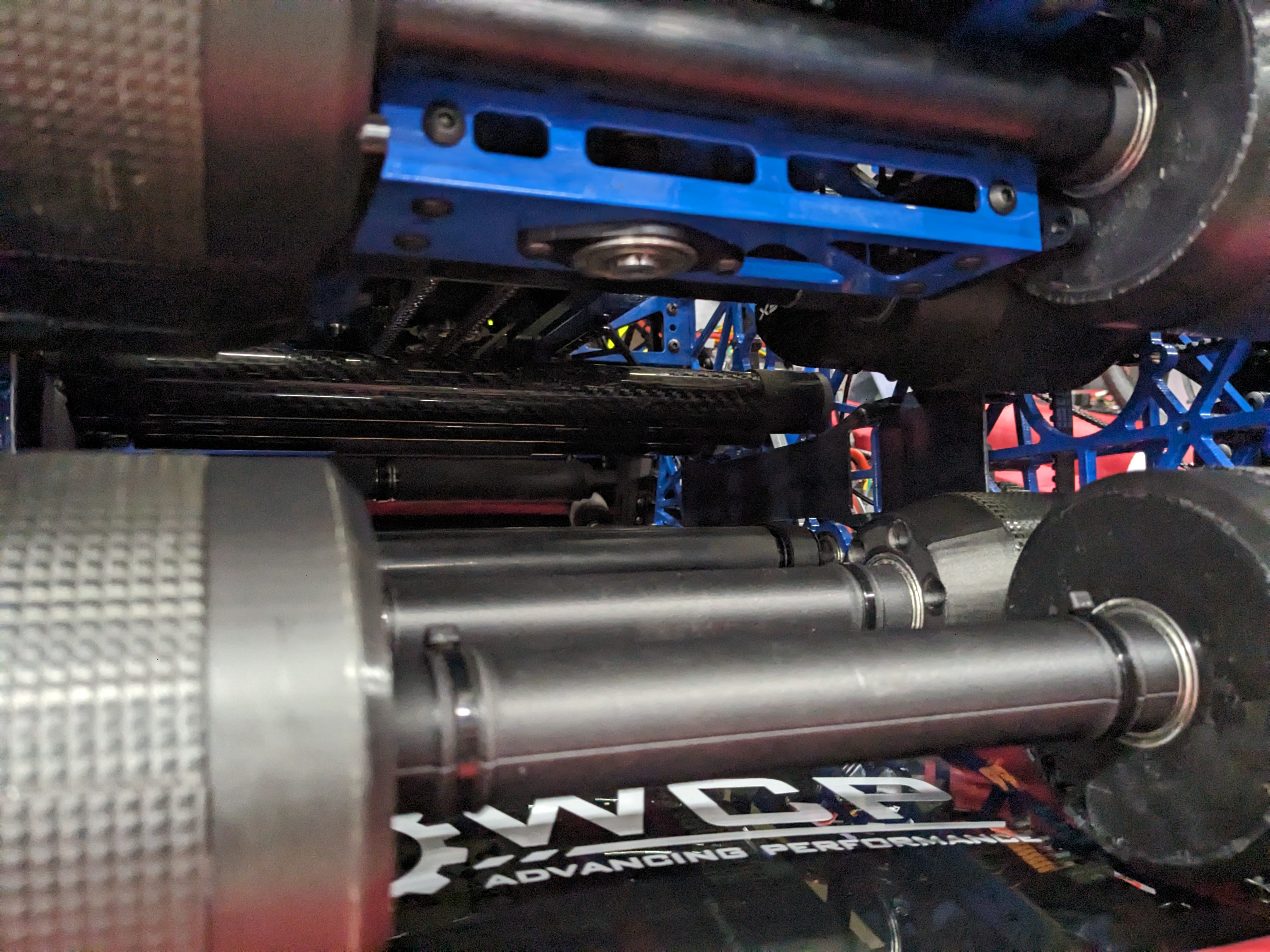

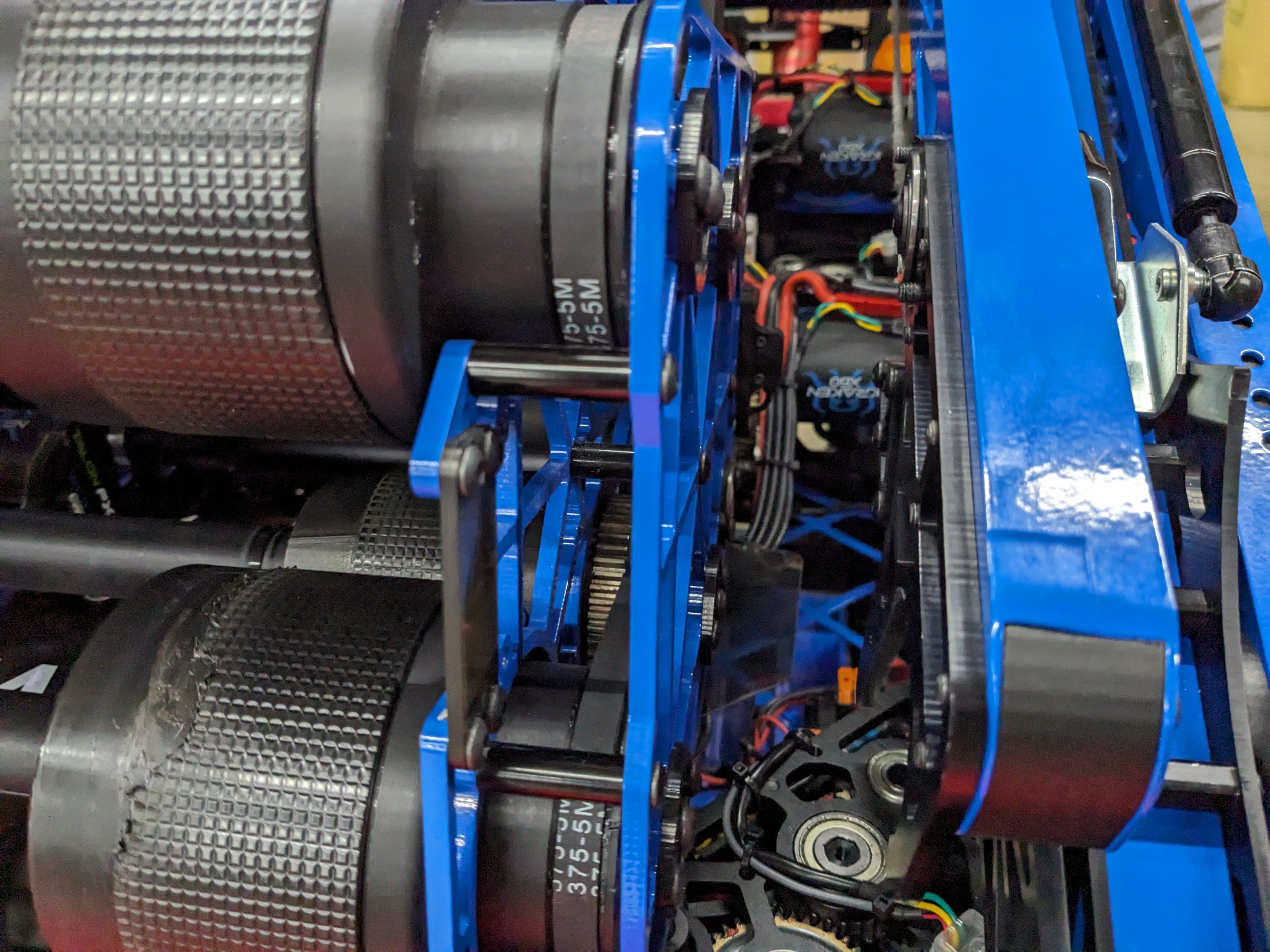

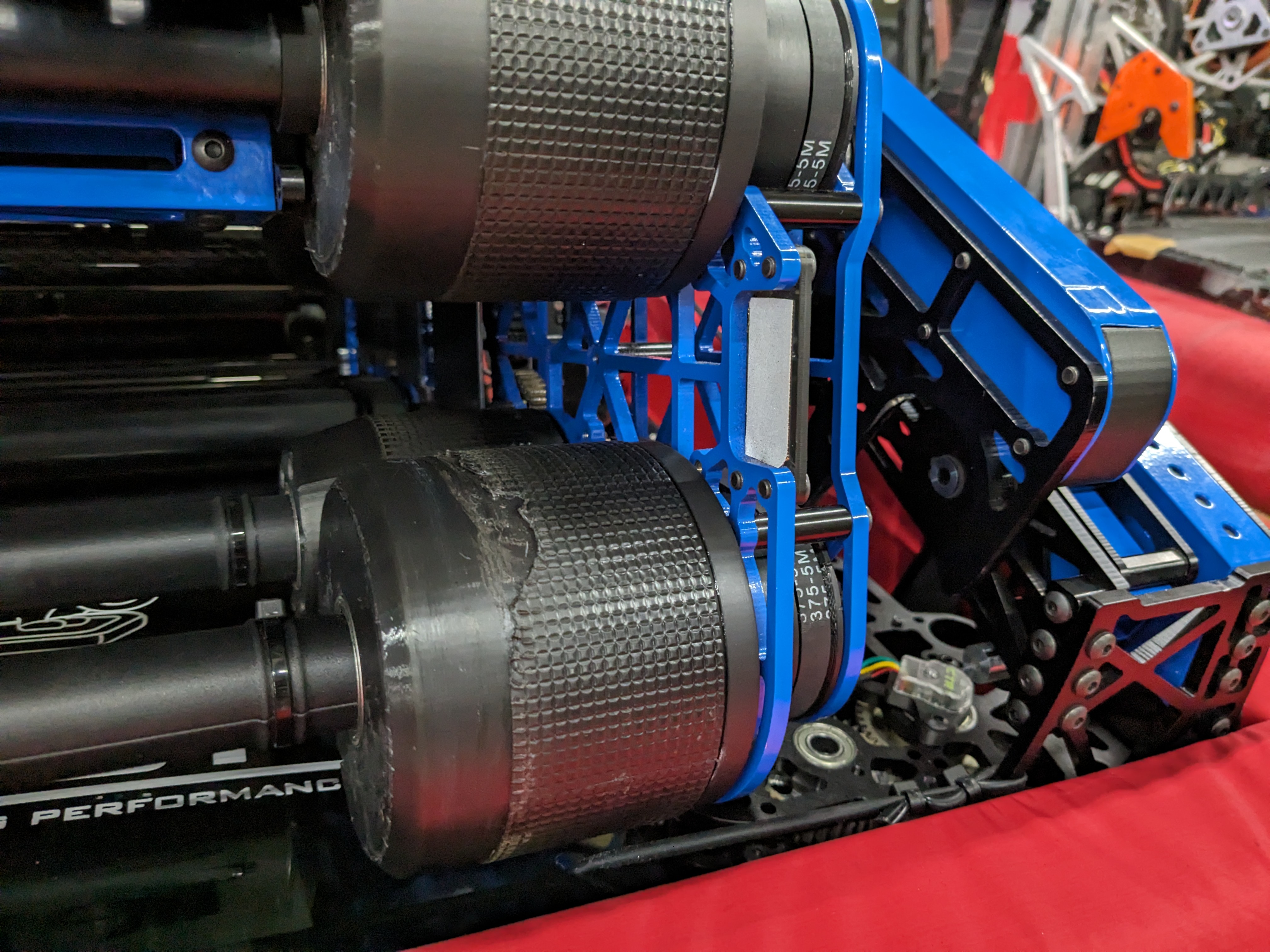

Between horizontal rollers is 65 belt with 32t pulleys

End horizontal roller to flywheel is 120 belt with 40 and 24t pulley

Horizontal roller reversal gears are 30t

Bottom Horizontal Rollers to reversal gear is 60 belt with 24t pulleys

Bottom horizontal roller to motor is 120 belt with 32 and 24 pulleys

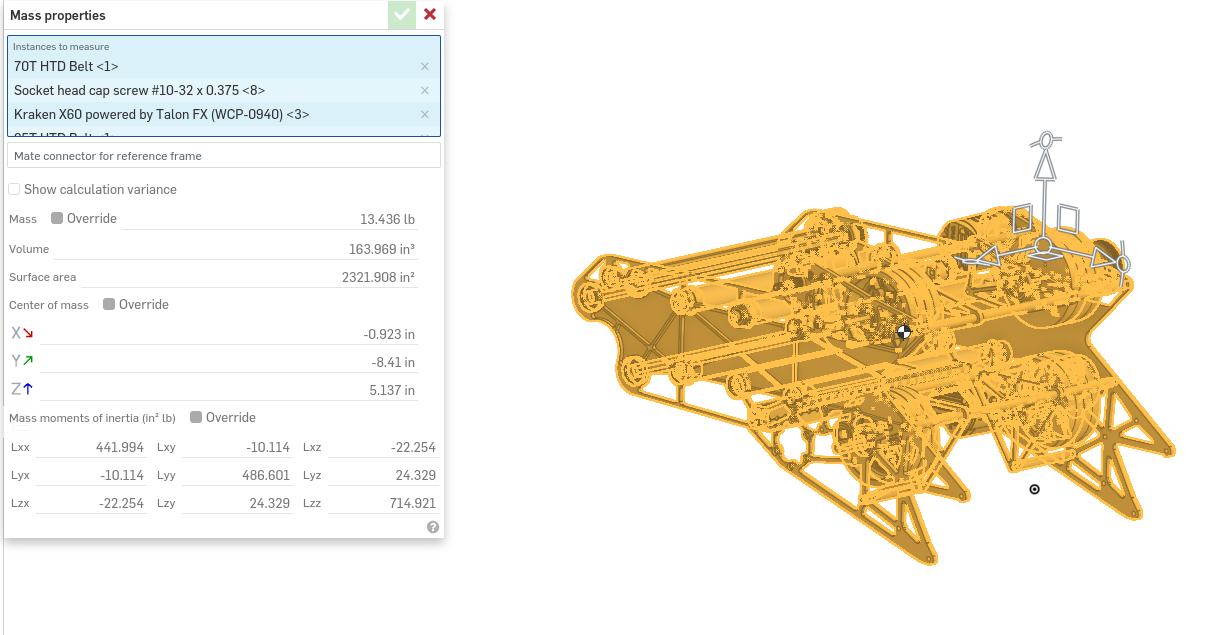

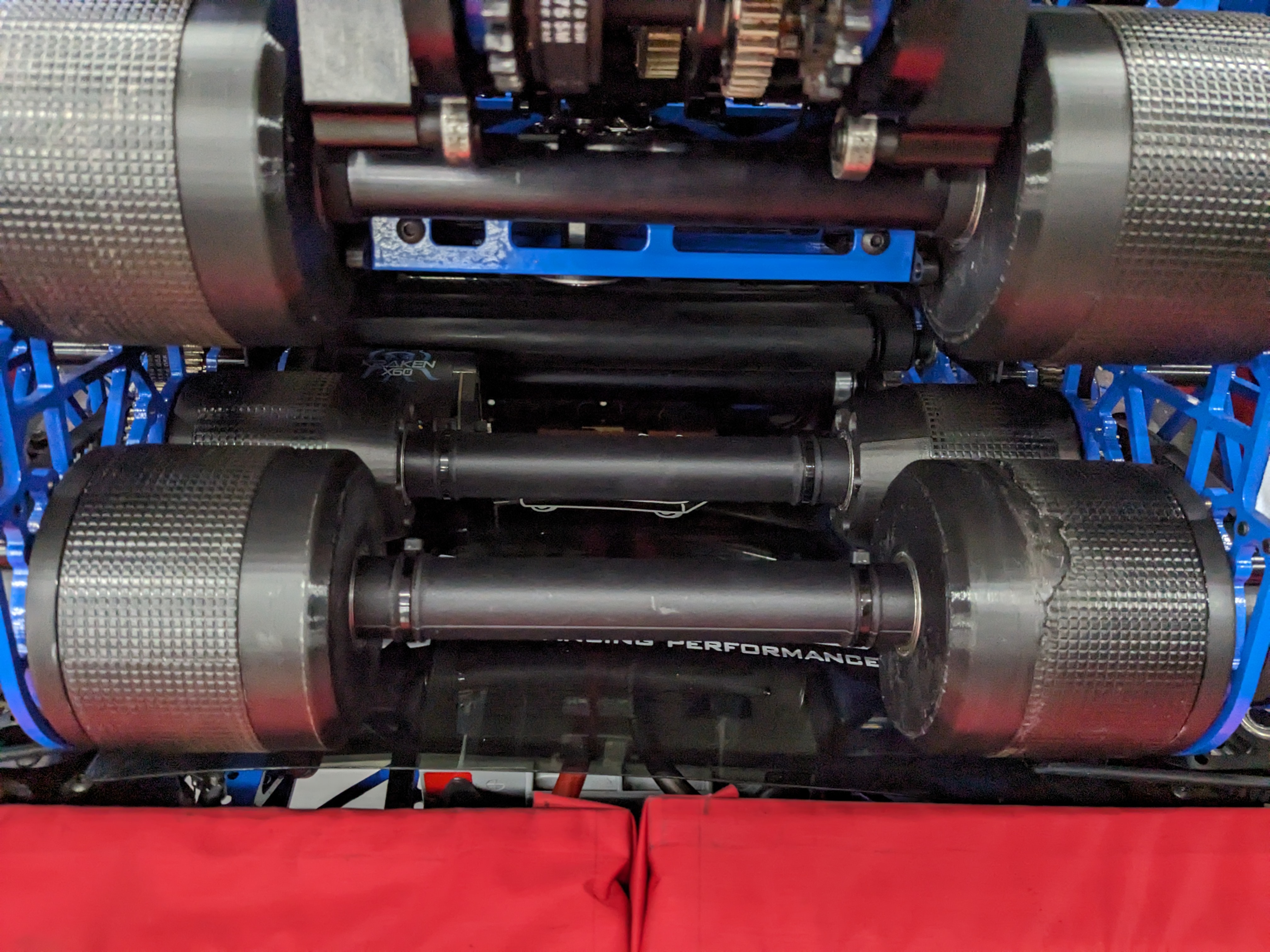

Between Vertical rollers 70 belt with 32 pulleys

Fast reversal gear is 30-30 OR 20-40 OR 44-16 OR 24-36

Across vertical rollers is 140 belt with 32 pulleys

Motor to vertical roller is 70 belt with 32 and 24 pulleys

Motor to slow roller is 50 belt with 18t pulleys

End roller to flywheel is 65 belt with 40 and 24t pulley

V2

24-24 - 45t is 2.067

V3

V4

V5

V6

Too much compression stalled the motor :(

V7

Features variable comrpession

Failed to spin fast enough (too much friction)

Compression Transition is too difficult for the shot to be good

V8

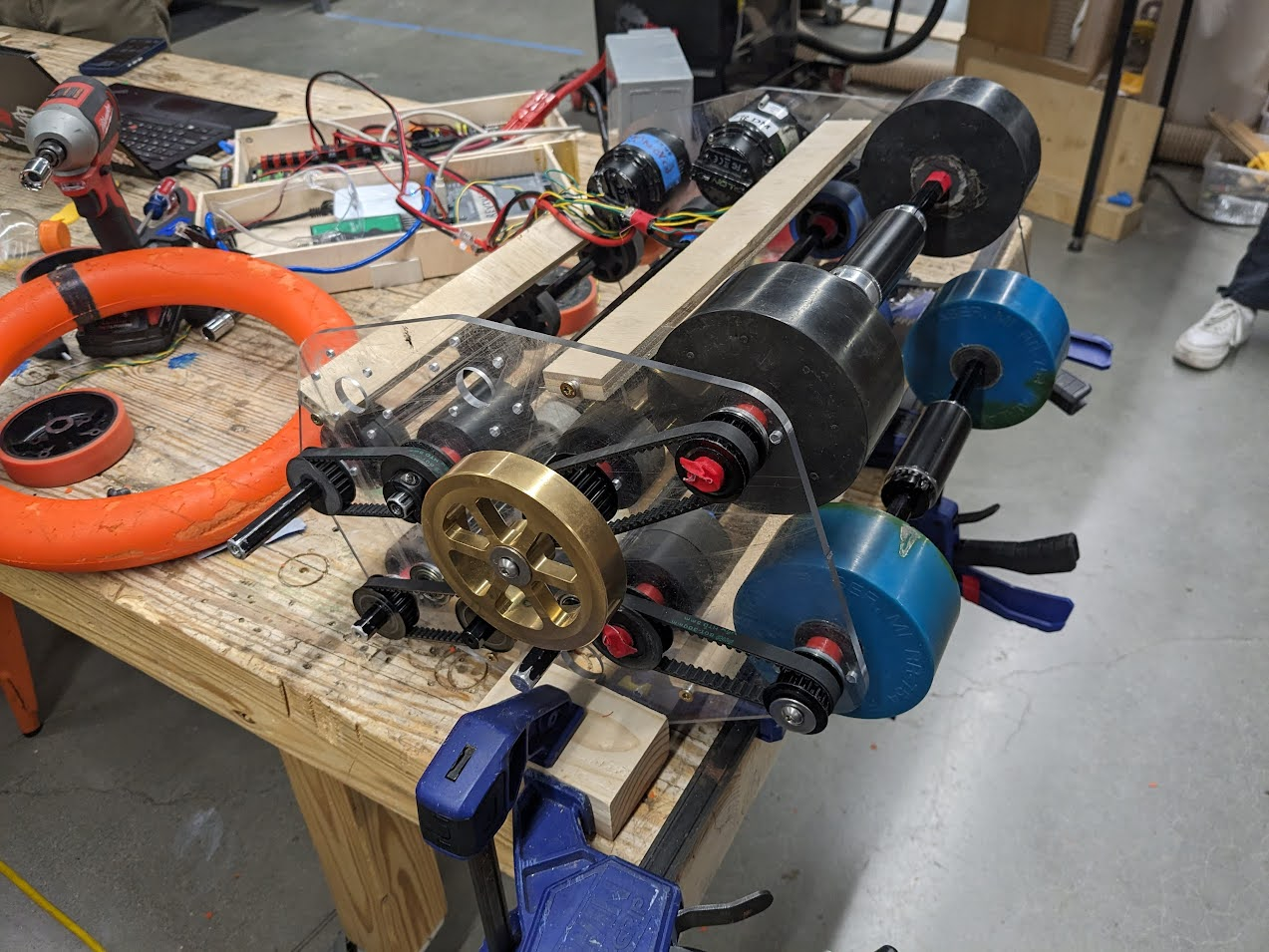

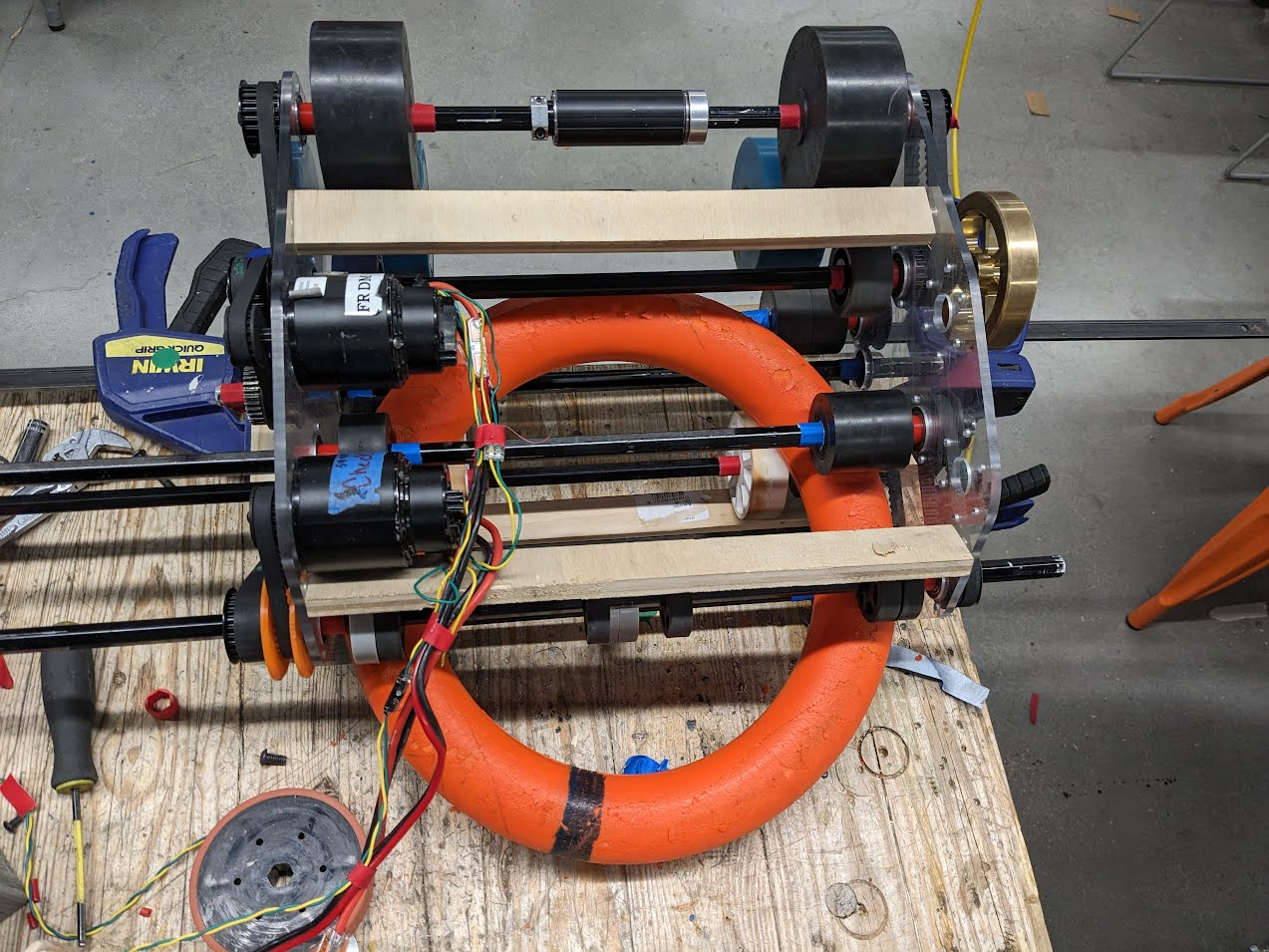

Trying single sided rollers, geared up 2:1, so low need everything to be low friction

It’s very difficult to transfer enough energy to the note for it to go fast enough. The above test was at ~9250 output RPM, which works out to 80 feet/second

V8.5

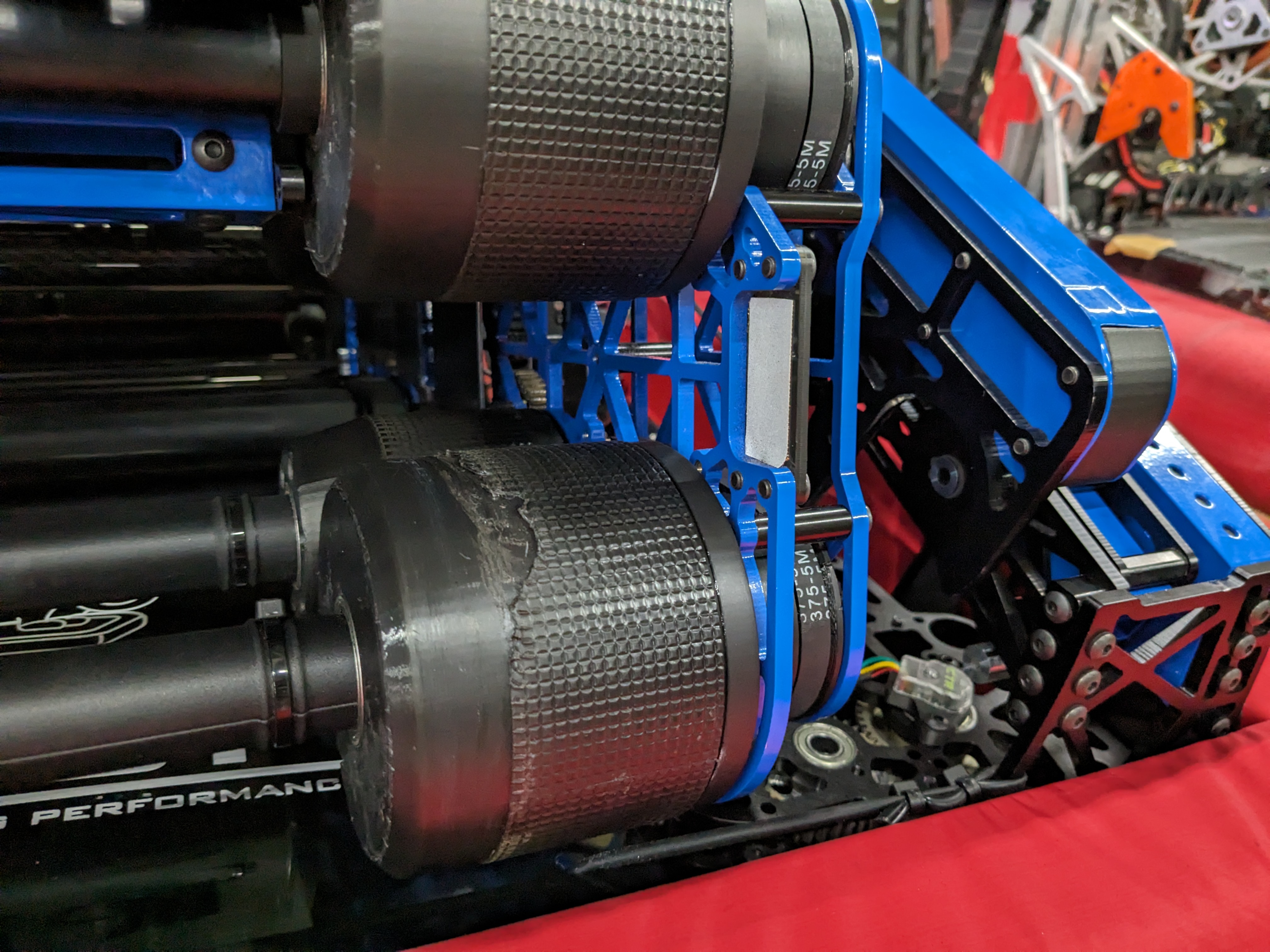

Adding grip tape significantly improved performance because the game piece kinda “rolls” out of the shooter instead of spinning in place

V9

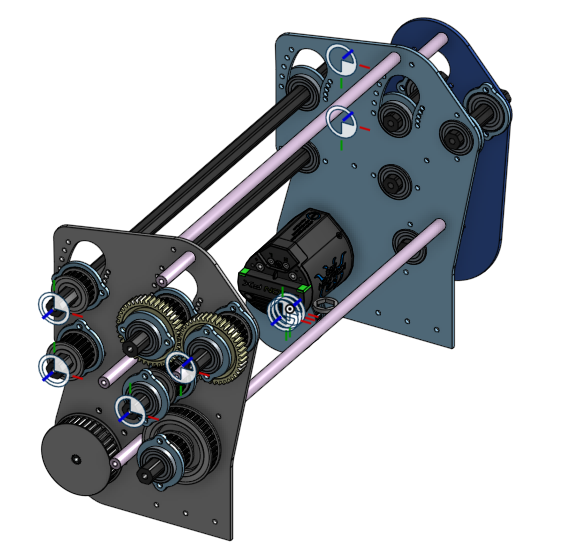

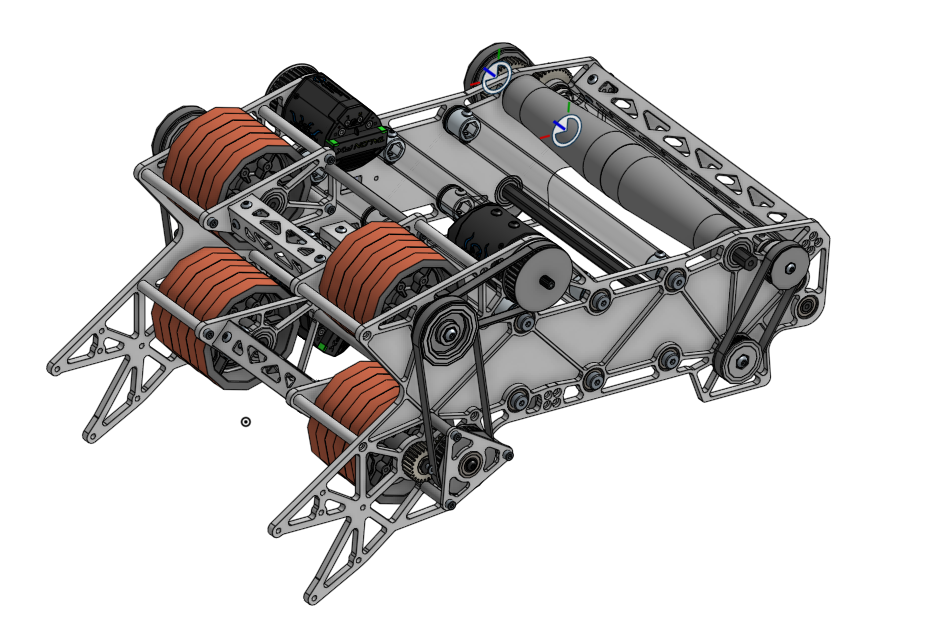

Taking inspiration for 6328 pod thing

First Test (50 RPS):

V10

Changes Needed:

-

3+7/8 wheels

-

Keep same compression on feeder with 2+3/8 wheels

-

beam break mounting

-

First idler a bit closer to feeder rollers

-

Tube for parallelogram

-

Motor not in path of note

V11

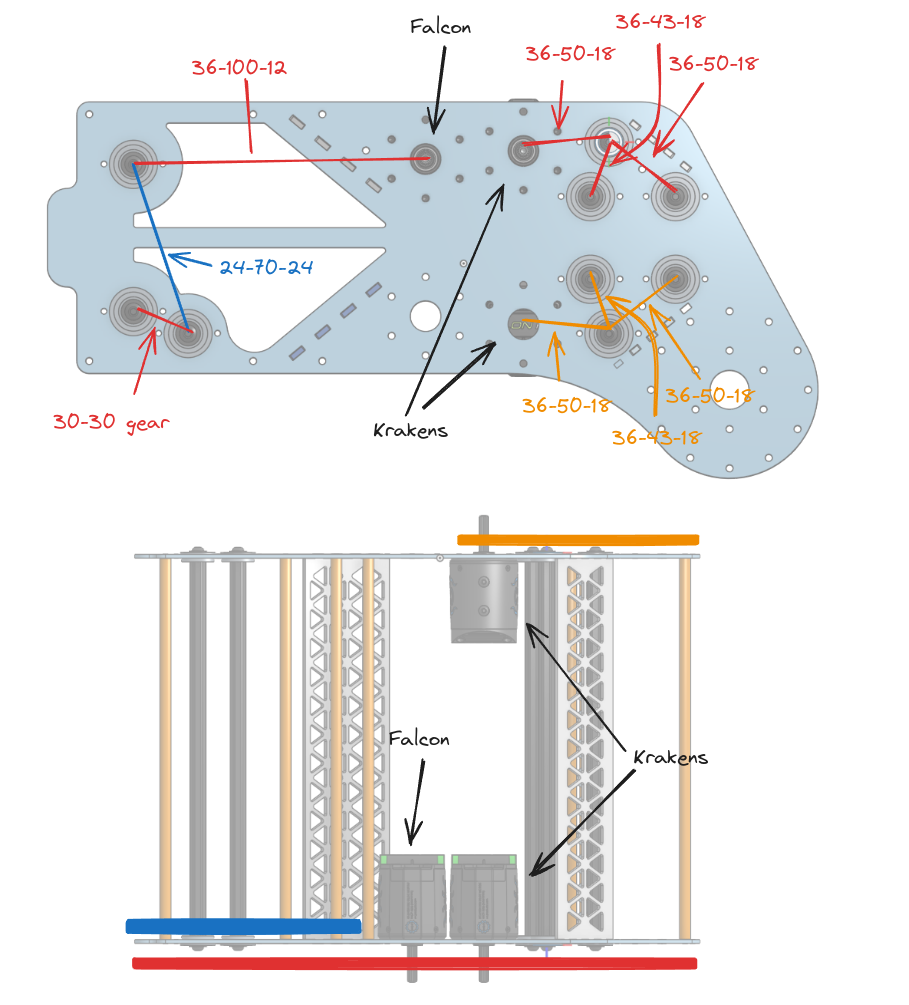

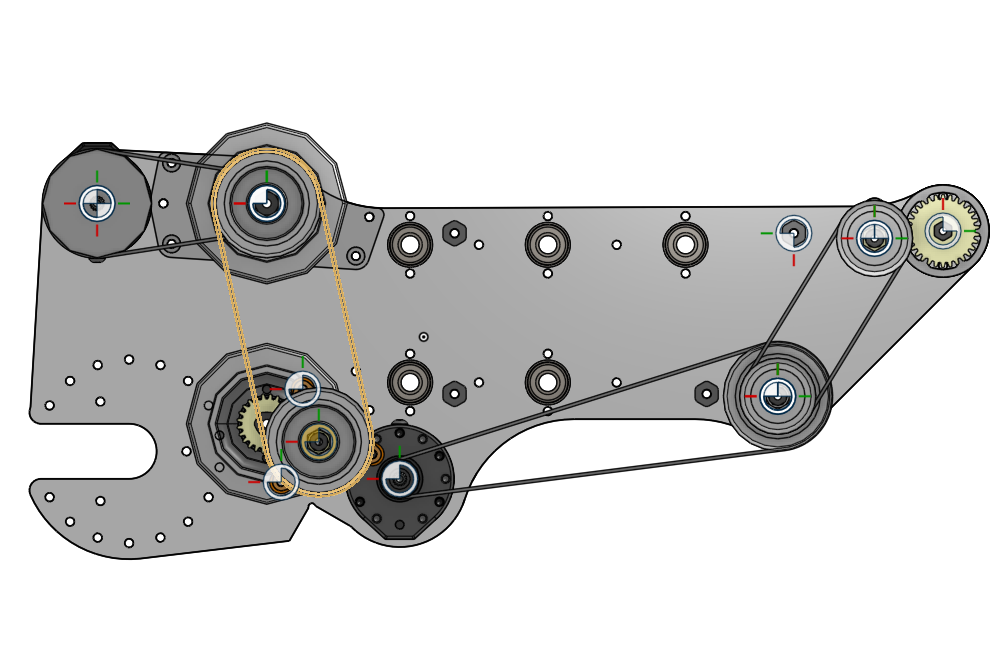

Cad Review:

- Cad nicer shiloh idler rolers

- More clearance on pod plate standoffs

- cad right length shafts

- add pulley to high speed reverser shafts

- spacers (Not in CAD)

-

Join pulleys for length reduction / backlash / not rounding out✅ 2024-03-07

Cad Review:

- Clearance for belt tensioner

- Back to 3:1 on feeder

- Cad feeder tubes

- Swap pulley with reverser plate

- make reverser plate bigger

settings

80, 49 - good

80, 59 - not good (breaker issues)

80, 59 - fine but unstable

80, 65 - less stable

80, 55 - more stable but still mid

90, 55 - more stable but mid

45, 60 - dips hard

35, 45 - wobbly

Try 8000, 5000 rpm…

V12

V13

v14

- Finish CAD 📅 2024-03-25 ✅ 2024-03-29

- Pass a ho review 📅 2024-03-26 ✅ 2024-03-29

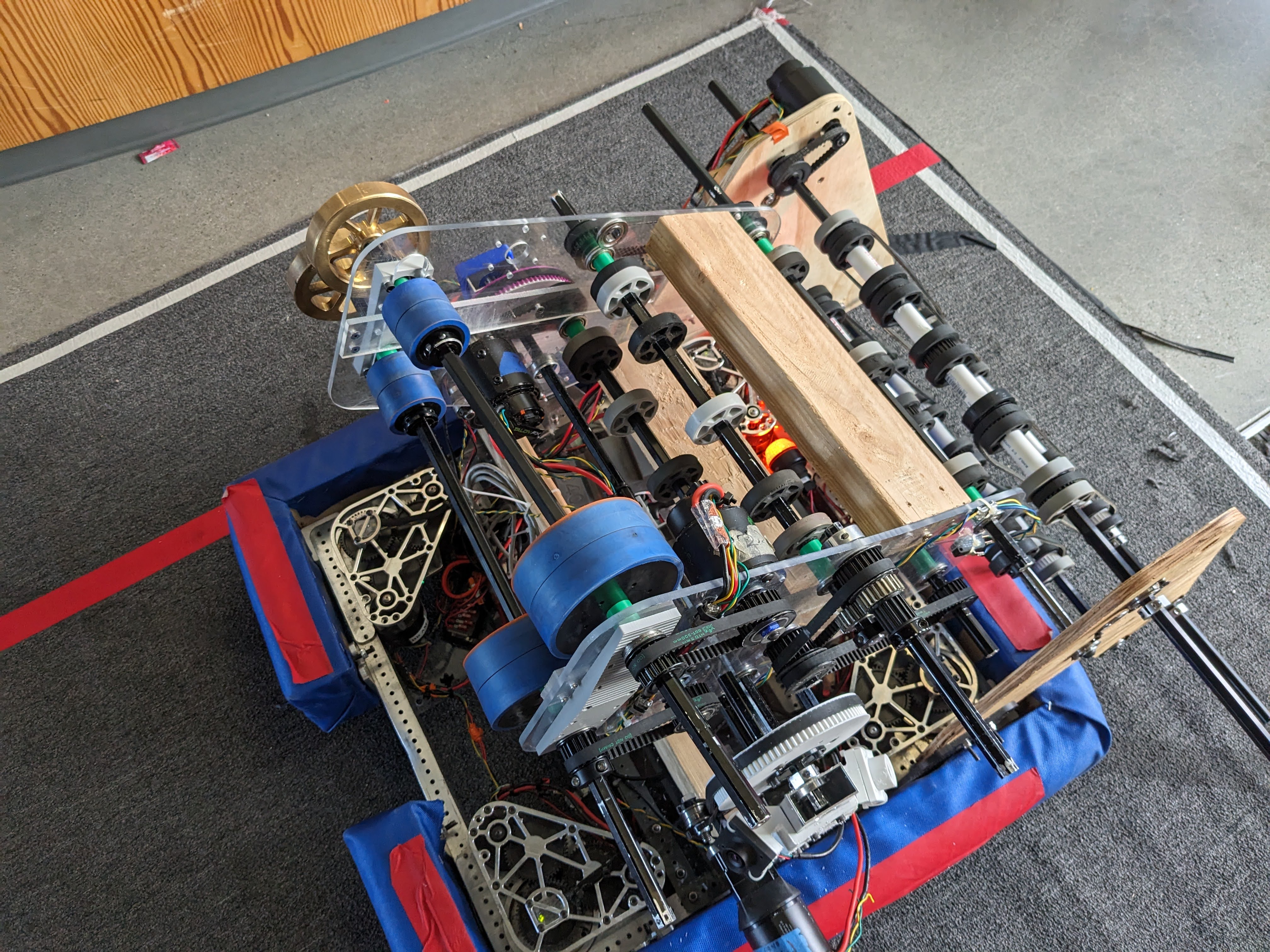

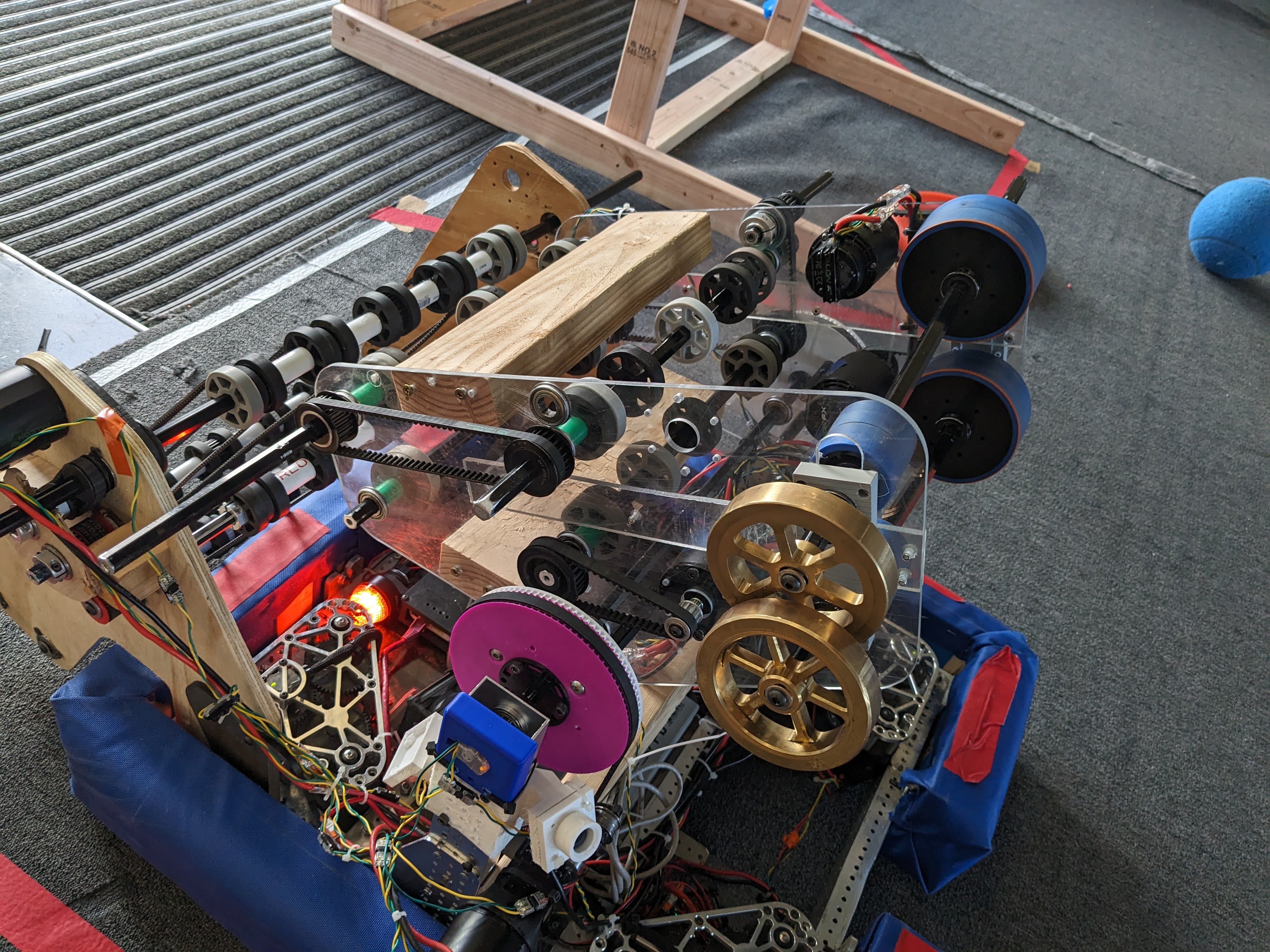

- build the fucking thing ✅ 2024-04-14

inspiration

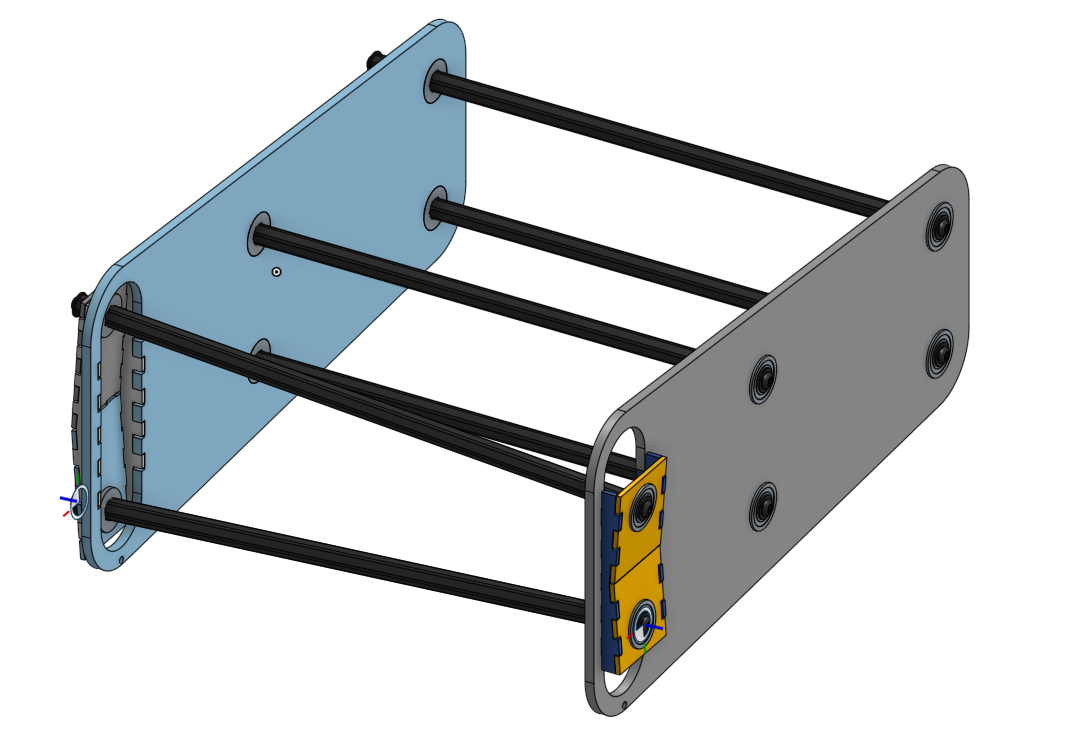

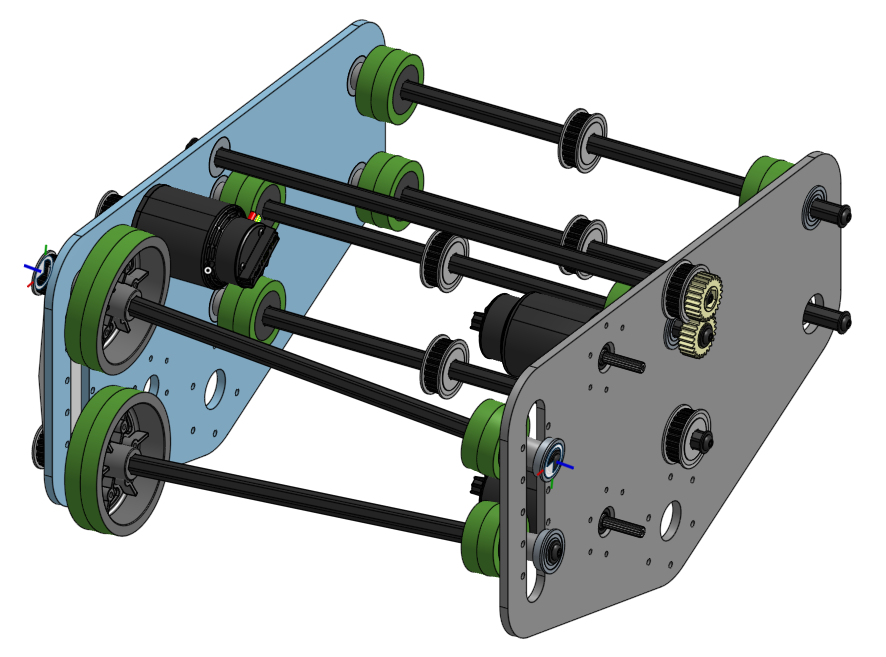

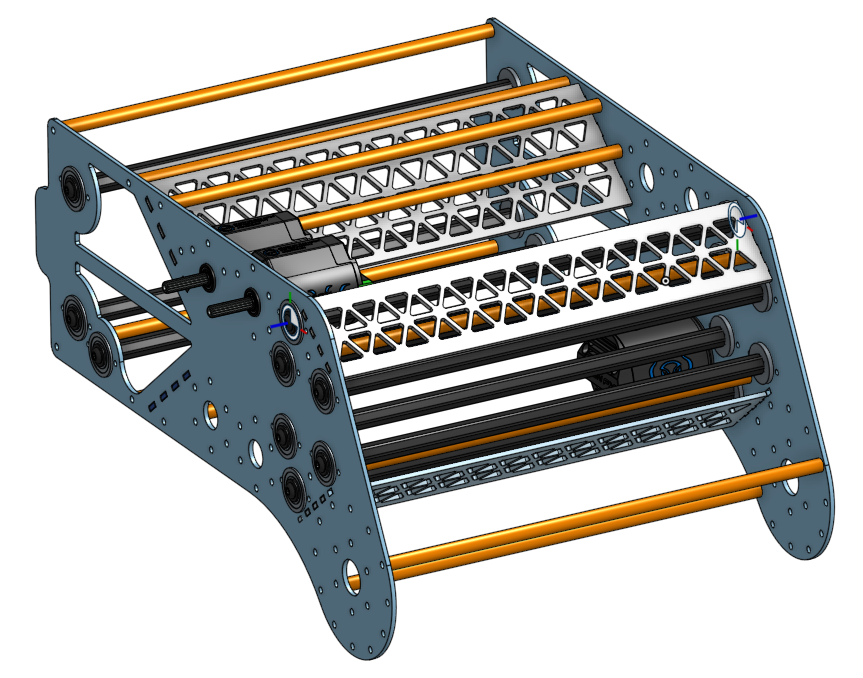

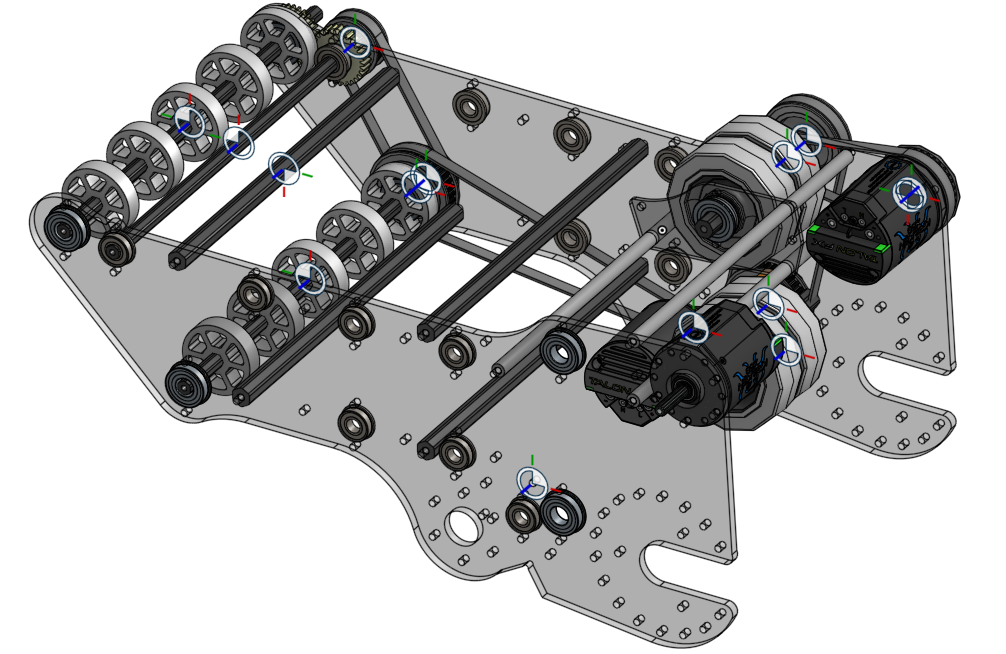

Design Techniques / Features

- Dual row 4” wheels

- Carbon dead axle

- high level of modularity

- cracked rigidity from 2x1

Cad Review tuesday march 26

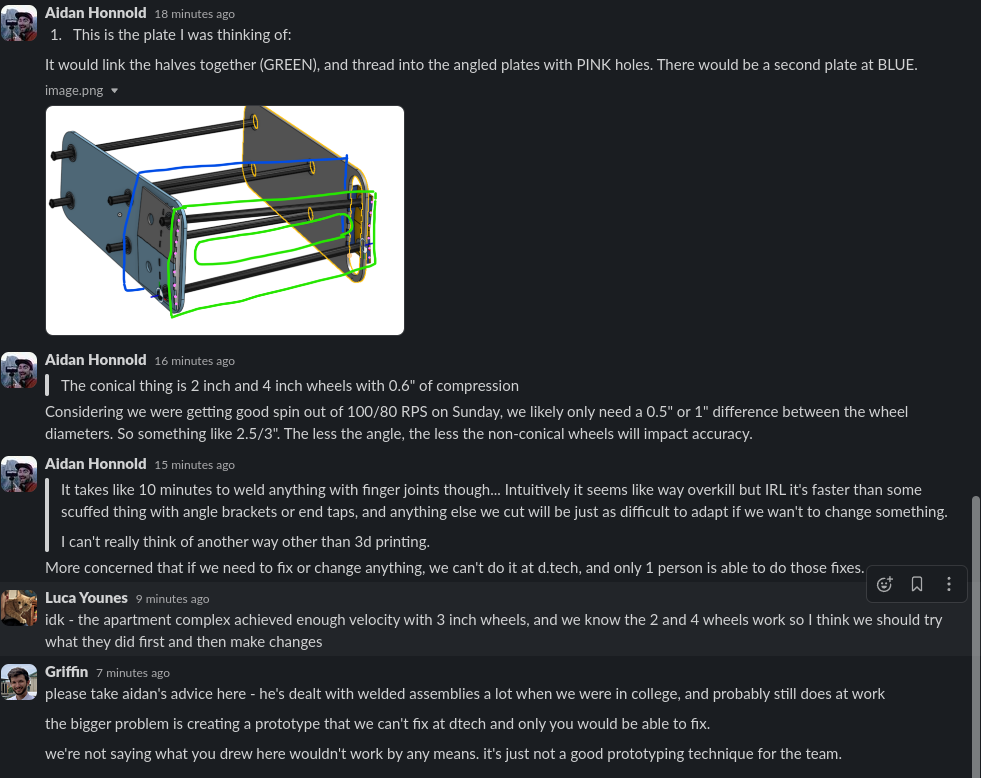

- High speed motor mounting plates not using same bolts as pivot ✅ 2024-03-27

- Feeder motor having top holes ✅ 2024-03-27

- [ ] Bend or Angle on high speed plate - 1/4 plateify high speed plate ✅ 2024-03-27

- bend, angle, or 1/4 on feeder motor mount ✅ 2024-03-27

- Delete tiny tiny gears ✅ 2024-04-08

- feeder note path tube extender thingy ✅ 2024-04-08

- bolt pattern instead of spline for reverser shaft ✅ 2024-03-27

- use cabron tube instead of standoffs on feeder ✅ 2024-03-28

- taper inside drums ✅ 2024-03-27

- dorito ✅ 2024-03-27

- gain 3 lb ✅ 2024-03-27

- groove drum for tape ✅ 2024-03-27

- undersize high speed belts 5 thou ✅ 2024-03-28

- beam break mounting ✅ 2024-03-28

Rectangle Tube Bending Calculation

Area moment of 1x1

Deflection at 30 lbs (Accelerating the end 3 lbs at 10 G’s)

Deflection at 150 lbs (Worst case robot loading)

Area moment of 1x2 (weak way)

Area moment of 1x2 (strong way)

Deflection at 30 lbs (weak way) (Accelerating the end 3 lbs

at 10 G’s)

Deflection at 30 lbs (strong way) (Accelerating the end 3 lbs

at 10 G’s)

Deflection at 150 lbs (strong way) (Worst Case Robot Loading)

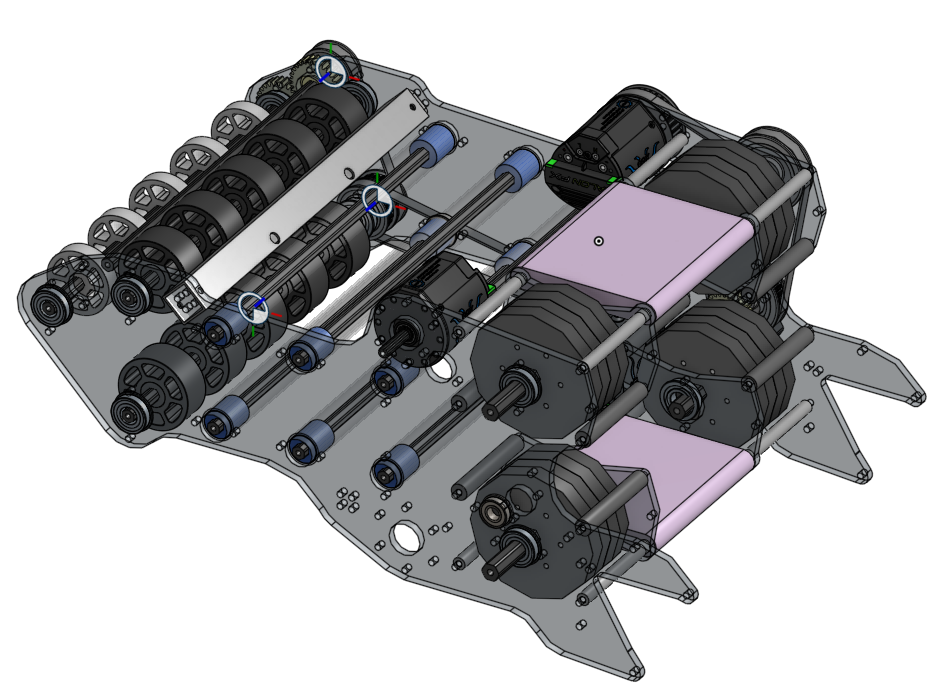

Cad Review wendesday march 27

- Bearing on reversing drum sits inside the gear so the print isn’t skinny af ✅ 2024-03-28

- extend tube forward for strength ✅ 2024-03-28

- 42-44 gear change ✅ 2024-03-28

- Nut plate tube attachment reinforcement ✅ 2024-04-08

Cad Review friday march 29

- Add spacer for gear plate ✅ 2024-03-29

- Make a shaft collar ✅ 2024-03-29

- Make ✅ 2024-04-08