Sound Deadening

I wanted to reduce the noises which I was hearing while driving, especially on the freeway.

I started by pulling the interior

I pressure washed and bleached the carpet and floor

Then installed a product called “siless”, which is an 0.08” thick butyl rubber sheet with a layer of aluminum. My understanding is by adding some heavy material which is very mechanically lossy, the noise from panel vibration is reduced.

I installed this material on the floor, back wall, inside the doors, and on the roof.

Seats

My stock 1.5 + 2 seats were old and tired, so I decided to swap them for some cheap PU leather seats from amazon.

I removed the stock seats and unbolted the rails from the seat buckets. The Driver and passenger side rails are mirrored exactly.

By drilling out 8 rivet looking things I was able to remove the upper part of the rails from the mounting bracket, which left me with just the mounting bracket

I just laid some short welds between the stationary part of the rails and the mounting brackets from the oem seats. The stock seatbelts are on their own “rails”, so my solution maintains the crash testing and safety isn’t relying on my poor quality welds

Center Console

Losing the 1.5 seat, I needed something in between the seats to act as an arm rest, and I wanted a few other features. Notably switches… lots and lots of switches.

I used a yard stick and a digital level app on my phone to reverse engineer the dash, floor, and inner edge of seats as best as I could.

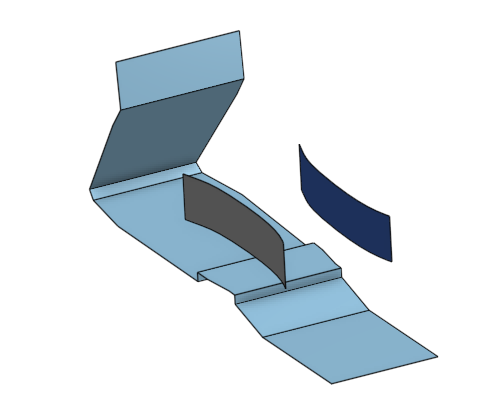

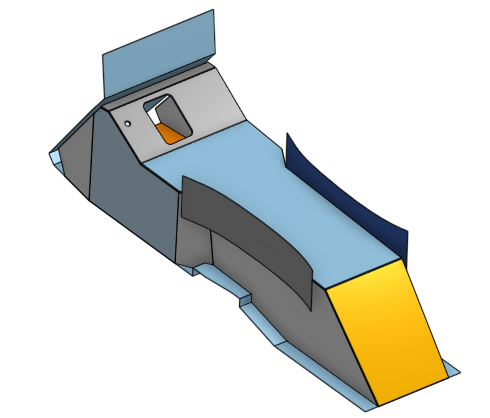

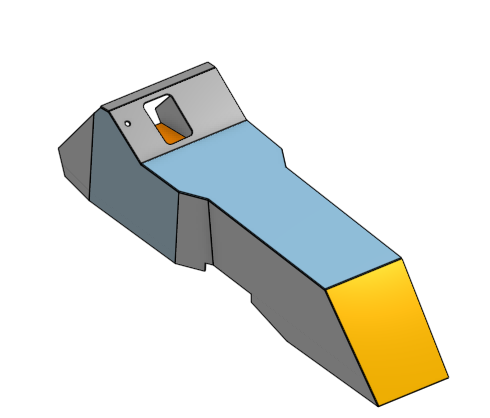

From there, I created a model of the relevant surfaces in CAD

I modeled a panel based center console to fit inside all the right shapes

I used a laser to cut all the panels out of semi-rigid cardboard paper stuff and taped them together to make a test part

I hacked out a larger hole for the shifter and marked a spot to shorten and steepen the back to

I would have marked out switch and control positions, but I didn’t have a pen in my car.